Application technique

Because the quality of the application is just as critical as the quality of the product, Thermoguard works with trained and certified applicators only. Contact us to find a Thermoguard applicator near you, or to become a licensed applicator yourself.

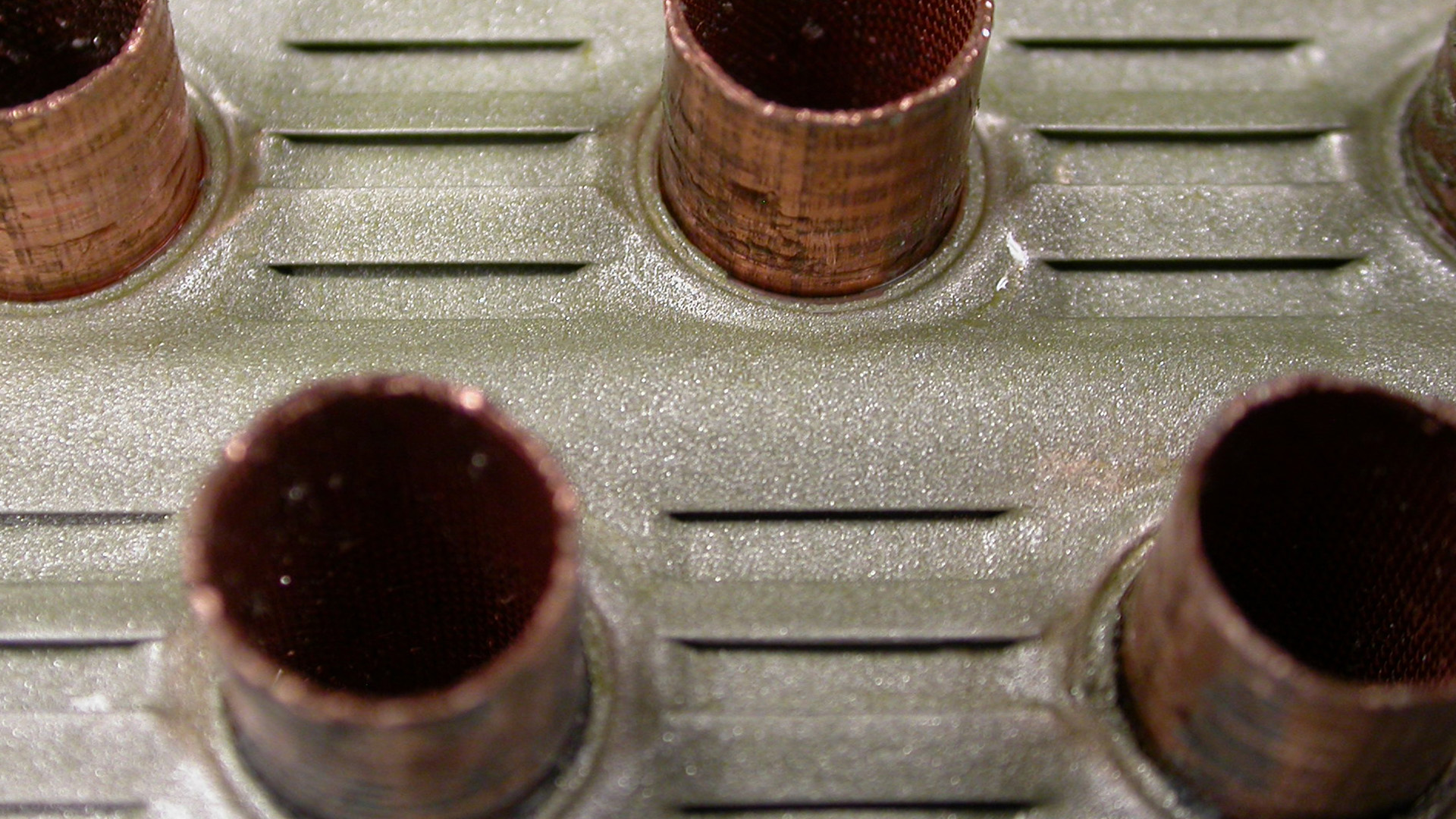

Unrivaled test results

Thermoguard has established a highly respected reputation in the HVAC/R industry as a High Quality corrosion protection option for heat exchangers, casing and cabinets. This reputation is supported by numerous test results, references and case studies. Contact us for more information.

Globally represented

Thermoguard is globally respresented by trained and qualified licensees only. Click here to find a licensee near you, or to become a licensee yourself.